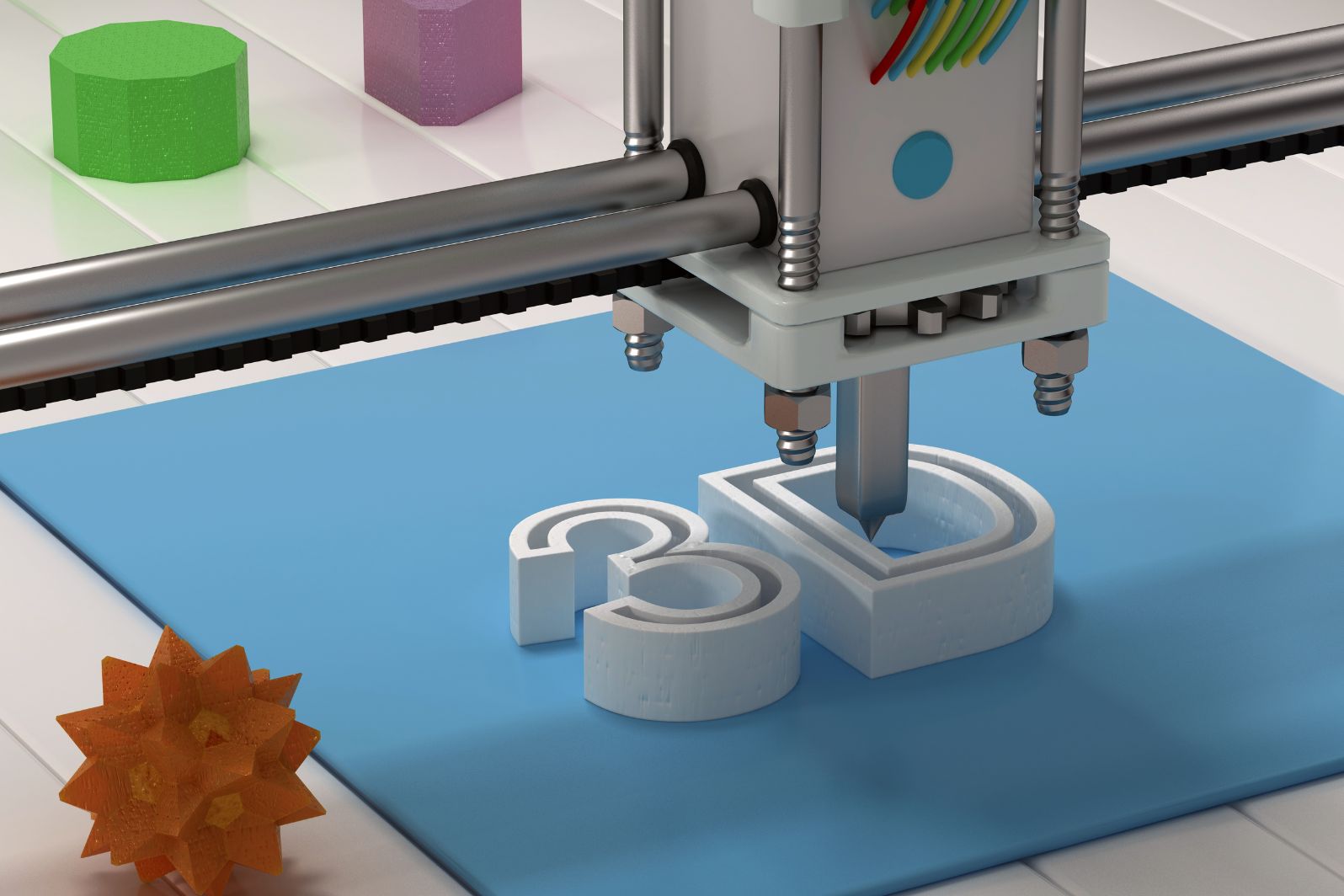

In the steadily developing scene of innovation, 3D printing has arisen as a notable power, changing enterprises and rethinking potential outcomes. Among its various applications, one region that has been especially reformed is prototyping. Customary prototyping strategies frequently include complex and tedious cycles, yet with the approach of 3D printing, development has been raised higher than ever. This article dives into the domain of 3D imprinting in prototyping, investigating its capability to reshape configuration, smooth out improvement, and speed up imagination.

The Power of Layered Creation

At its core, 3D printing—also known as additive manufacturing—builds objects layer by layer from a digital model. This layer-by-layer approach enables designers and engineers to materialize their ideas with an unprecedented level of precision and detail. Whether it’s a small-scale intricate model or a large-scale functional prototype, visit this site to learn more about how 3D printing allows for the creation of complex geometries that were previously unattainable through conventional methods.

Speeding Up Iteration Cycles

Prototyping is about emphasis — refining plans, testing functionalities, and making upgrades. In this iterative cycle, there isn’t a moment to spare. Conventional prototyping techniques frequently include difficult work, forms, and tooling, which can broaden the emphasis cycles altogether. 3D printing, then again, slices the time expected for every emphasis. Plan changes can be made quickly in the computerized model, and another model can be printed inside the space of hours, in the event that it is not minutes. This sped-up cycle engages planners to investigate more plan choices, prompting a more refined final result.

Cost Efficiency and Material Optimization

Customary prototyping strategies frequently include the utilization of materials and assets, adding to the general expense. 3D printing offers cost productivity that would be useful by utilizing just the essential measure of material to construct the article, limiting waste. Moreover, the capacity to model with a scope of materials, from plastics to metals to ceramics, empowers fashioners to test different material properties without focusing on enormous scope creation.

Complexity Meets Functionality

One of the most convincing highlights of 3D printing is its capacity to coordinate complex functionalities straightforwardly into the model. Customary strategies could require separate parts and unpredictable get-together cycles. With 3D printing, complex gatherings can be combined into a solitary printed piece, diminishing the requirement for get together and upgrading the model’s exhibition. This joining of structure and capability makes the way for creative plans that can consistently consolidate style with common sense.

Customization and Personalization

3D printing is a hero of customization. In the realm of prototyping, this implies that fashioners can make models custom-fitted to explicit necessities and client needs. Whether it’s a clinical gadget, customer item, or engineering model, 3D printing empowers the development of stand-out models that take care of individual details. Using a 3d viewer for obj files can further enhance the design process by allowing designers to visualize, inspect, and refine their 3D models before printing, ensuring optimal results. This customization viewpoint saves time as well as opens roads for customized client encounters.

Breaking Geographical Barriers

The advanced idea of 3D printing implies that models can be shared across topographical areas easily. Configuration records can be communicated on the Internet, permitting groups from various areas of the planet to team up flawlessly. This angle is especially pertinent in the present globalized plan and assembling scene, where joint effort is not generally restricted by actual vicinity.

Future Prospects and Beyond

As 3D printing innovation keeps on propelling, its effect on prototyping is probably going to escalate. The joining of new materials further developed printing methods, and improved programming abilities will additionally extend the skylines of prototyping. From quick emphasis to on-request fabricating, the capability of 3D imprinting in prototyping is boundless.

All in all, 3D printing has impelled the specialty of prototyping to exceptional degrees of effectiveness and advancement. Its capacity to make perplexing plans, speed up emphasis cycles, and tweak models has changed the manner in which architects and designers approach item advancement. As the innovation keeps on developing, we can hope to observe significantly more creative and noteworthy applications, further setting 3D printing’s job as a foundation of advancement in prototyping.